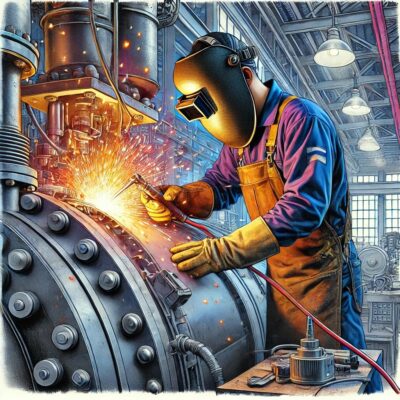

Boilermakers fabricate, assemble, install, and repair boilers, tanks, and other large containers used in industries such as power generation, manufacturing, and shipping. They work with metal components to ensure the safety and efficiency of these systems.

What is a typical day as a Boilermaker?

– Reading and interpreting blueprints and technical drawings to understand project requirements

– Assembling or repairing boilers, tanks, and pressure vessels by welding, bolting, or riveting metal components

– Inspecting systems for leaks, corrosion, or wear and tear, and performing maintenance as needed

– Conducting pressure tests to ensure the integrity of tanks or boilers

What else might they be expected to do?

– Operate heavy machinery to shape or cut metal components

– Apply protective coatings to prevent corrosion in boilers or tanks

– Collaborate with engineers and safety inspectors to ensure compliance with regulations

What type of training is needed for this career path?

– A technical diploma or certificate in welding, metalwork, or boiler-making is required.

– Apprenticeships or on-the-job training programs provide essential hands-on experience.

– Certifications in welding or pressure vessel fabrication, such as ASME (American Society of Mechanical Engineers) standards, enhance career prospects.

What kind of personality is needed to excel in this career path?

– Practical, detail-oriented, and safety-conscious individuals thrive in this role.

– Big 5 traits: Conscientiousness and Emotional Stability.

– Myers-Briggs types: ISTP or ESTP often align with this career.

What kind of interests do people in this career path have?

– Passion for working with metals and creating durable structures (Realistic and Conventional traits).

– Interest in construction, engineering, and manufacturing processes.

– Interests & Aptitude: Conventional (C), Realistic (R), and Investigative (I).

Are there any innate skills or aptitudes required?

– Strong manual dexterity and hand-eye coordination for working with tools and metal parts

– Problem-solving skills to address design or fabrication challenges

– Physical stamina to handle demanding tasks, such as heavy lifting and working in confined spaces

What challenges can I expect to face if I pursue this career path?

– Managing physically demanding work in extreme conditions, such as high heat or enclosed spaces

– Balancing tight deadlines with the need for precise craftsmanship

– Staying updated on advancements in welding and metal fabrication technologies

What are the job prospects for this path in Kenya and Africa? What about International prospects for a Kenyan citizen?

– Kenya and Africa: Boilermakers are in demand in industries such as energy, construction, and manufacturing. Opportunities also exist in the oil and gas sector.

– International: Kenyan professionals with certifications in global standards can access roles in international manufacturing companies, shipyards, or energy infrastructure projects.

What should I focus on if I choose to pursue this career?

– Gain proficiency in welding and metal fabrication techniques.

– Build practical experience through apprenticeships or industrial training programs.

– Obtain certifications for working with pressure vessels and advanced welding techniques.

Which other careers or job roles can I progress to?

– Welding Inspector or Quality Control Specialist

– Maintenance Technician for Industrial Boilers

– Project Manager in Manufacturing or Energy Sectors

– Trainer or Instructor in Boilermaking and Welding

– Consultant for Metal Fabrication Projects